Electrical

adjustments are required after replacing circuit components and certain mechanical

parts. It is important to perform these adjustments only after all repairs and replacements

have been completed.

Also, do not attempt these adjustments unless the proper equipment is

available.

Equipment

Required

1. Setup remote control

2. Color Analyzer,

CA-310 (KONICA MINOLTA Luminance meter) or

measuring instrument as good as CA-310.

To

set up the service mode

1. Turn the

power on.

2. Wait for the TV to go to Live mode.

3. Press [RC5 GUEST], [0], [6], [2], [5], [9], [6] and [RECALL/INFO] on the

setup remote control in this order. The following screen will appear.

Purity

Check Mode

This mode cycles through full-screen displays of red, green, blue, and white to

check for non-active pixels.

1. Enter the service mode.

2. Each time the [7] button on the setup remote control is pressed, the display

changes as shown below.

3. To cancel

or to exit from the Purity Check Mode, press [BACK/PP] button.

White

Balance Adjustment

White Balance

Adjustment should be performed when replacing the LCD Panel or Digital Main

CBA.

Symptom of

Misadjustment: White becomes bluish or reddish.

Operate the

unit for more than 60 minutes.

2. Enter the service mode.

3. Press [TV VOL -] button three times on the setup remote control to select

“Drive setting” mode. “Drive-” appears in the screen.

4. Set the color analyzer at the CHROMA mode and zero point calibration. Bring

the optical receptor pointing at the center of the LCD-Panel.

[The optical

receptor must be set perpendicularly to the LCD Panel surface.]

5. Press [3] button to select the “HDB” for High Drive Blue adjustment. (“HDB”

appears in the screen.)

6. Press [HOME/MENU] button. The internal Raster signal appears in the screen.

(“Internal (Single)” appears in the upper right of the screen as shown below.)

7. Press [P +

or -] buttons to adjust the color temperature becomes 12000°K (x= 0.272 / y=

0.278 ±0.005).

8. Press [1] button to select the “HDR” for High Drive Red adjustment (“HDR”

appears in the screen.) and press [P + or -] buttons to adjust the color temperature.

9. If necessary, adjust the “HDB” or “HDR” again.

10. Press [9] button to select the “LDB” for Low Drive Blue adjustment (“LDB”

appears in the screen.) and press [P + or -] buttons to adjust the color temperature.

11. Press [7]

button to select the “LDR” for Low Drive Red adjustment (“LDR” appears in the

screen.) and press [P + or -] buttons to adjust the color temperature.

12. Press [8] button to select the “LDG” for Low Drive Green adjustment (“LDG”

appears in the screen.) and press [P + or -] buttons to adjust the color temperature.

13. If necessary, adjust the “LDB”, “LDR” or “LDG” again.

14. Press [TV VOL -] button to shift to the “Debugging Message” mode.

If there is no message under “[WB]” section, this adjustment completes.

If “Drive settings are NG. Retry.” is displayed, repeat above steps from 5. to

13. Then check “Debugging Message” again. If “Drive settings are NG. Retry.” is

displayed, replace the LCD Panel or Digital Main CBA.

15. To cancel or to exit from the White Balance Adjustment, press [BACK/PP]

button.

To

initialize the TV

Initialization

is to place the set in a new out of box condition. The customer will be

prompted to select a language and program channels after the set has been

initialized.

To put the program back at the factory-default, initialize the LCD TV using the

following procedure.

[Disconnect any device from the USB

Port before you conduct on this procedure.]

1. Turn the power on.

2. Enter the service mode.

3. Press [RC5 GUEST] button on the setup remote control.

4. Press [RECALL/INFO] button to proceed with the self check mode.

5. Make sure to confirm the “INITIALIZED : OK” appear in the green screen.

6. Unplug the AC Cord and plug it back on again.

Note: To cancel the service mode, press [Power ] button on the setup remote

control.

Firmware

renewal

Upgrading of

the TV software via IP, USB or RF. It also allows the configuration of the Auto

Update feature to enable the TV to be automatically upgraded.

Note: Auto Update feature is only available with IP or RF upgrade.

Source: “IP”,

“USB”, “RF” – This function allows you to select the Source from which the TV

Upgrade data will be received.

Note: The USB source is bidirectional (TV can read from the USB or write to the

USB), but IP and RF sources are read only.

Like the TV Clone function, the RF option requires a GNA installed in the

property head end to broadcast the data to the TVs. For more information,

contact your P&F sales representative.

Upgrade Type:

“All”, “Software”, “Assets”, “Clone”, “P:I Key”

C This section allows you to select the type of software to be upgraded to the

TV. (All 5 upgrade types are available if you select USB as source)

• If set to ALL, then all elements (Software, Assets, Clone and P:I Keys) will

be upgraded, based on their version and the version check setting.

• If set to Software, the Stand-By MCU, SPI MCU and the SOC will be upgraded.

• If set to Assets, the slideshow graphic assets will be upgraded.

• If set to

Clone, Setup menu settings and channel map elements will be upgraded.

• If set to P:I Key, the TV will attempt to switch mode to FTG or PPV, provided

that the correct key for its serial number is present.

Of these, only the Assets and Clone types are bidirectional. The All, Software,

and P:I Key types are read only. If either Assets or Clone is selected, an

additional menu item, Direction, appears.

Direction:

• “To TV” (reads data from the USB, copies it to the TV)

• “From TV” (reads data from the TV, copies it to the USB

Version

Check: “On”, “Off” - If set to Yes, this feature causes the TV to perform a

version check of the TV upgrade software to ensure that only a newer version

will be installed.

Start - This

function will initiate the TV upgrading process.

Auto Update:

“4 Hour”, “1 Hour”, “30 Min”, “10 Min” - When TV goes into standby, Auto Update

will automatically check for new TV upgrades and upgrade the TV software and/or

clone data after 4

hour, 1 hour, 30 min or 10 min if newer versions are found. Like all previous

RF download functions, this too requires a GNA to be installed in the property head

end.

RF Channel

Number.

Indicates major. Minor channel where upgrading data is available.

Hotel

TV mode

Capturing a

Clonefile (TV to USB)

• All TV Setup menu settings and the TV channel map will be copied from the TV

to the attached USB storage device.

• Any existing clone data on the USB storage device will be overwritten.

• All the key input and the shutdown timers will be invalid during the cloning

process.

• Audio and Video will be muted during the cloning process.

How

to capture a clone file from the TV to a USB storage device

1. Insert a USB storage device into the TV USB port. (It must have sufficient

free space to hold a TV clone file - about 5 MB.)

2. Press the [RC5 SETUP] and [HOME/MENU] button on the setup remote control to

enter the setup menu.

3. Scroll down to and select “Upgrades”.

4. Select “Source” and select “USB” then press the [OK] button.

5. Select “Type” and select “Clone” then press the [OK] button.

6. Select “Direction” and select “from TV” then press the [OK] button.

7. Select “Execute” and select “Start” then press the [OK] button.

8. After the successful completion, “Upgrade Completed! Press OK to continue”

message appears on screen.

[Upon

successful completion at Step 8, make sure to press the [OK] button once. If

[OK] button is pressed twice, the cloning process will restart.]

Installing

a Clonefile (USB to TV)

• All TV Setup menu settings and the TV channel map will be copied from the USB

storage device to the TV.

• All the key input and shutdown timers will be invalid during the cloning

process.

• Audio and Video will be muted during the cloning process.

• If any illegal data is encountered in the clonefile, the cloning process will

be aborted.

• After the successful completion of the cloning process, the new set of values

will be adopted by the TV.

To

install a clone file from a USB storage device to the TV

1. Insert the USB flashdrive containing the clonefile into the TV USB port

2. Press the [RC5 SETUP] and [HOME/MENU] button on the setup remote control to

enter the setup menu.

3. Scroll down to and select “Upgrades”.

4. Select “Source” and select “USB” then press the [OK] button.

5. Select “Type” and select “Clone” then press the [OK] button.

6. Select “Direction” and select “To TV” then press the [OK] button.

7. Select “Execute” and select “Start” then press the [OK] button.

8. After the successful completion, “Upgrade Completed. Press OK to continue” message appears on

screen.

9. After pressing OK, the TV will restart and initializewith the new values.

Status

menu screen (optional)

1. Turn the power on.

2. Press the [RC5 SETUP] and [RECALL/INFO] button on the setup remote control

in this order to display the status menu.

You can switch the screen by using [>] or [<] button.

3. Press the

[BACK/PP] button to exit the status menu.

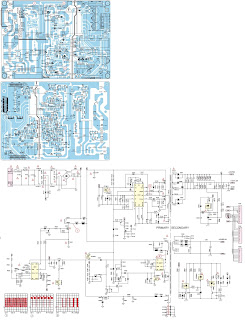

SMPS

and back-light inverter schematic