Test

& Alignment: Pre-Conditions

and DC/DC Check

Before power on, please check the board according to the

relevant block diagram and circuit diagram, and make sure that no serious issue

or mistake can destroy the board. For example, the output of DC/DC and LDO

should not be shorted to ground.

Supply a suited voltage and power-on, then check the voltage according to the relevant block diagram, circuit diagram and voltage specification within 5% margin.

For example, check SoC voltage (AV3V3, VCCK-1V2, etc.), DDR voltage (DDRV) , amplifier voltage (Main_Power), etc… Only the standby voltage is necessary if there is no software in the flash.

Supply a suited voltage and power-on, then check the voltage according to the relevant block diagram, circuit diagram and voltage specification within 5% margin.

For example, check SoC voltage (AV3V3, VCCK-1V2, etc.), DDR voltage (DDRV) , amplifier voltage (Main_Power), etc… Only the standby voltage is necessary if there is no software in the flash.

SW Image

download

Download the latest release SW from below FTP server:

* Link:xxxxx

* Username: xxxxx* Password: xxxxx* Folder: xxxxx

Download the latest release SW from below FTP server:

* Link:xxxxx

* Username: xxxxx* Password: xxxxx* Folder: xxxxx

OAD Transport Stream Image

To manage quicker mass reflashing, a predefined OAD DVB-T channel (freq:850MHz / bandwidth:8MHz) is embedded to SW core and only available into Factory mode. Some licensed IBL tools ('xxx2lli.exe', 'lli2dsm.exe',

dsmmerge.exe, …) from Intellbyte Inc. might be necessary to create appropriate DVB SSU TS. Over some predefine settings such as repeated datablock insertion, null packets size, … (controllable in configuration file), here below are mandatory OUI entries structure to prepare DSM-CC carousel image format:

To manage quicker mass reflashing, a predefined OAD DVB-T channel (freq:850MHz / bandwidth:8MHz) is embedded to SW core and only available into Factory mode. Some licensed IBL tools ('xxx2lli.exe', 'lli2dsm.exe',

dsmmerge.exe, …) from Intellbyte Inc. might be necessary to create appropriate DVB SSU TS. Over some predefine settings such as repeated datablock insertion, null packets size, … (controllable in configuration file), here below are mandatory OUI entries structure to prepare DSM-CC carousel image format:

Note ⑴: SW Entry are referring to following PKG image file name “V8-0MT310x-LF1Vyyy.pkg”

Note ⑵: See enclosed necessary Data Broadcast Carousel configuration file format details (DBC)

Note ⑵: See enclosed necessary Data Broadcast Carousel configuration file format details (DBC)

|

OUI Entry

|

MT31L

|

MT31B

|

MT31LB

|

|

CUST_OAD_OUI

|

408BF6

|

408BF6

|

408BF6

|

|

CUST_OAD_HW_MODEL

|

0x5881

|

0x5881

|

0x5881

|

|

CUST_OAD_HW_VERSION

|

0x0001

|

0x0001

|

0x0001

|

|

CUST_OAD_SW_MODEL

(x)

|

0x3101

|

0x3102

|

0x3102

|

|

CUST_OAD_SW_VERSION

(yyy)

|

0x0xxx

|

0x0xxx

|

0x0xxx

|

‘bin2dsm.exe -v -v -v -m0,0,"TCL_HW5881",0

-n200 -z102400 -nz -o%FILE%.dsm -h"OUI=CUST_OAD_OUI

model=CUST_OAD_HW_MODEL version=CUST_OAD_HW_VERSION vm=0xffff" -s"OUI=CUST_OAD_OUI

model=CUST_OAD_SW_MODEL version=CUST_OAD_SW_VERSION vm=0xffff" %FILE%.pkg’

Then, OAD TS can be completed using below command and arguments:

‘dsmsectn.exe -v -dvbssu -mpegts -patpmt -nit_ter -sdt -o%FILE%.ts -gTCL_HW5881.dbc %FILE%.dsm’

For more robustness, TS can be played with following presets such as modulation:QAM-64, guard interval:1/8, coding rate:2/3 to ensure ~22Mbps.

OAD reflashing process is managed within 4 steps operation: multiplex detection, DVB transfer, flashing and warm-start.

model=CUST_OAD_HW_MODEL version=CUST_OAD_HW_VERSION vm=0xffff" -s"OUI=CUST_OAD_OUI

model=CUST_OAD_SW_MODEL version=CUST_OAD_SW_VERSION vm=0xffff" %FILE%.pkg’

Then, OAD TS can be completed using below command and arguments:

‘dsmsectn.exe -v -dvbssu -mpegts -patpmt -nit_ter -sdt -o%FILE%.ts -gTCL_HW5881.dbc %FILE%.dsm’

For more robustness, TS can be played with following presets such as modulation:QAM-64, guard interval:1/8, coding rate:2/3 to ensure ~22Mbps.

OAD reflashing process is managed within 4 steps operation: multiplex detection, DVB transfer, flashing and warm-start.

UART &

IR Parser

To use both UART and/or IR parser, TV has to be set in Factory mode with its VGA port well connected to suitable UART device or an IR emitter device correctly facing up TV (see below “Product Assembly - section 2.0”

how to activate “Factory key”).

The SoC’s RS232 mode is automatically enabled at power-on and doesn’t require any command initialization frame. <0x30 0x30 0x30 0x2E 0x30 0x65 0x30 0x74 0x30 0x0D 0xE2> from host to TV.

So correctly setup UART parser engine for further serial communication, it’s necessary to send following command frame <0xAA 0x06 0x10 0x01 0xA7 0xEF> within following COM presets 115200/8/n/1; “PS” caption might be toggled and displayed on bottom left screen (“S” like Serial) if successful.

To communicate with TV depending on SIACP revision layout implementation, you may need to fulfill UART/IR commands protocol and format described on enclosed SIACP requirements document (rev. v5.9).

To use both UART and/or IR parser, TV has to be set in Factory mode with its VGA port well connected to suitable UART device or an IR emitter device correctly facing up TV (see below “Product Assembly - section 2.0”

how to activate “Factory key”).

The SoC’s RS232 mode is automatically enabled at power-on and doesn’t require any command initialization frame. <0x30 0x30 0x30 0x2E 0x30 0x65 0x30 0x74 0x30 0x0D 0xE2> from host to TV.

So correctly setup UART parser engine for further serial communication, it’s necessary to send following command frame <0xAA 0x06 0x10 0x01 0xA7 0xEF> within following COM presets 115200/8/n/1; “PS” caption might be toggled and displayed on bottom left screen (“S” like Serial) if successful.

To communicate with TV depending on SIACP revision layout implementation, you may need to fulfill UART/IR commands protocol and format described on enclosed SIACP requirements document (rev. v5.9).

ProjectID

Modification

There are different IDs stored into system memory depending on different Panels settings and Models features, but there’s only one key branching ProjectID that includes all. So, it’s not recommended to modify PaneID with

Hyper terminal as other ID features may not change.

To modify ProjectID, you need to go through “Factory menu > Other > Project info > Project ID”, and then spin left or right with RCU “◄/►” key” keys to suitable ID (Project name is dynamically refreshed)

There are different IDs stored into system memory depending on different Panels settings and Models features, but there’s only one key branching ProjectID that includes all. So, it’s not recommended to modify PaneID with

Hyper terminal as other ID features may not change.

To modify ProjectID, you need to go through “Factory menu > Other > Project info > Project ID”, and then spin left or right with RCU “◄/►” key” keys to suitable ID (Project name is dynamically refreshed)

Here below is none exhaustive ProjectID

table for reference. Project list and all relative information are dispatched

and updated as a new firmware package is released.

Project Name

|

Project ID

|

Panel

|

L39F3303F

|

001

|

PANEL_CMI_V390HJ1-P02

|

L39F3393F

|

002

|

PANEL_CMI_V390HJ1-P02

|

L32F3303

|

003

|

PANEL_SS_LSC320AN02

|

L32F3393

|

004

|

PANEL_SS_LSC320AN02

|

39FU5253C

|

005

|

PANEL_CMI_V390HJ1-LE1

|

39FU5253CW

|

006

|

PANEL_CMI_V390HJ1-LE1

|

39FU5243C

|

007

|

PANEL_CMI_V390HJ1-LE1

|

55FU4243C

|

008

|

PANEL_SS_LSC550HJ03_8

|

32HU5253C

|

010

|

PANEL_SS_LSC320AN02

|

32HU5253CW

|

011

|

PANEL_SS_LSC320AN02

|

32HU5243C

|

012

|

PANEL_SS_LSC320AN02

|

…

|

||

L28T3540

|

087

|

Once the boards (chassis, KB, IR, PSU…) and the panel are

well interconnected, plug all suitable signals generator to relevant below

inputs/outputs using respective test patterns format to check picture/sound

quality:

Picture/Video formats and Audio tones

can be changed by the factory according to their own standard and broadcasted

signals (ie: 1KHz & 3KHz, sweep, …)

AD Calibration

Test

N/A

As SoC as built-in A/D self-calibration mechanism, there’s not any ADC to perform.

N/A

As SoC as built-in A/D self-calibration mechanism, there’s not any ADC to perform.

DDC &

EDID & T-Link Test

The E-EDID data structures are according to VESA Enhanced EDID 1.4a (and EIA/CEA-861B for HDMI)..

All VGA and HDMI structures have their own BIN profile which are part of firmware and uploaded at power-on.

For EDID check, it’s recommended to check whether the correct EDID is uploaded by checking corresponding

EDID NVM Checksum or read them out to check bit by bit if it is in line with the released EDID bin file.

The E-EDID data structures are according to VESA Enhanced EDID 1.4a (and EIA/CEA-861B for HDMI)..

All VGA and HDMI structures have their own BIN profile which are part of firmware and uploaded at power-on.

For EDID check, it’s recommended to check whether the correct EDID is uploaded by checking corresponding

EDID NVM Checksum or read them out to check bit by bit if it is in line with the released EDID bin file.

How to upgrade HDCP KEY by UART

For HDCP compliancy, it’s needed to

check whether the HDCP key has been well set by connecting suitable generator

signal

IP Return

Test

“How to upgrade MAC address using

USB”

All MT31 series platform support IP return function according to CI+ v1.3.

Here are some representative code example:

All MT31 series platform support IP return function according to CI+ v1.3.

Here are some representative code example:

40-8B-F6-90-4D-53

Factory

Menu (Service mode)

Follow the below steps to pop-up the Factory menu in case of “Factory Key” is disabled:

* Press RCU “MENU” key to display main menu

* Select “Picture” and press “OK” key to enter into Picture submenu.

Follow the below steps to pop-up the Factory menu in case of “Factory Key” is disabled:

* Press RCU “MENU” key to display main menu

* Select “Picture” and press “OK” key to enter into Picture submenu.

Scroll down to “Contrast” item.

* Press the sub-sequence RCU keys “9” “7” “3” and “5”

In case of “Factory Key” is enabled, just press RCU “Return” key to pop-up again the Factory menu.

The status of “Factory Key” can be changed in “Factory Menu > Hotkey”

Press RCU “OK/►” key to enter the submenu.

Press RCU “Menu” key to go back to the root menu.

Press RCU “◄/►” key to change the values.

Press RCU “OK” key run the function.

Press RCU “Exit” key exit the Factory menu.

In case of “Factory Key” is enabled, just press RCU “Return” key to pop-up again the Factory menu.

The status of “Factory Key” can be changed in “Factory Menu > Hotkey”

Press RCU “OK/►” key to enter the submenu.

Press RCU “Menu” key to go back to the root menu.

Press RCU “◄/►” key to change the values.

Press RCU “OK” key run the function.

Press RCU “Exit” key exit the Factory menu.

Factory Captions

While “Factory Key” is enabled,

there’re some toggled display information (2s) relative to SW, ProjectID, CI+, NetworkID to facilitate 100% quick screening without accessing to whatever else

menu:

Firmware Version (MV) -

‘V8-0MTxxxx-LF1Vyyy’

Project ID (ID) - range [000..999]

CI Key Activation flag (CI+) - ‘NO’= no key, ‘YES’= key activated

HDCP Key (HDCP) - ‘NULL’= no key, ‘YES’= key activated

PVR flag (ERG) - ‘OFF’= disabled, ‘ON’= enabled

P (Production/Factory mode flag) / S (Factory UART Parser mode flag) / W (Warm-Up mode flag).

Project ID (ID) - range [000..999]

CI Key Activation flag (CI+) - ‘NO’= no key, ‘YES’= key activated

HDCP Key (HDCP) - ‘NULL’= no key, ‘YES’= key activated

PVR flag (ERG) - ‘OFF’= disabled, ‘ON’= enabled

P (Production/Factory mode flag) / S (Factory UART Parser mode flag) / W (Warm-Up mode flag).

Channel

Map Preset

Region channel Maps are stored in the firmware and can be directly preloaded via Factory menu.

Other faster methods via UART/IR commands are available on enclosed SIACP requirements.

Region channel Maps are stored in the firmware and can be directly preloaded via Factory menu.

Other faster methods via UART/IR commands are available on enclosed SIACP requirements.

Factory Menu Description: Warm-up Test

Following TCL standard and practices, it’s required minimum 15min of Warm-Up that can be considered as Burn-In. Additional Aging for White Balance alignment is no more necessary due to consistent Picture Performance

with Cloning usage.

This function is accessible by selecting “Factory menu à Burning Mode”, pressing RCU “OK/►” key, to release/disable Burn-in mode, it’s just required to press “Menu” button from local keyboard. Other faster methods

via UART/IR commands are available on enclosed SIACP requirements.

Following TCL standard and practices, it’s required minimum 15min of Warm-Up that can be considered as Burn-In. Additional Aging for White Balance alignment is no more necessary due to consistent Picture Performance

with Cloning usage.

This function is accessible by selecting “Factory menu à Burning Mode”, pressing RCU “OK/►” key, to release/disable Burn-in mode, it’s just required to press “Menu” button from local keyboard. Other faster methods

via UART/IR commands are available on enclosed SIACP requirements.

White

Balance (WB) Cloning; White Balance Touch-Up (Golden sample)

As some color coordinates discrepancies can be noticed from panel batches to others, it may necessary to perform slight touch-up.

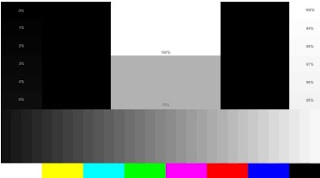

For Color temperature adjustment, switch TV on leading HDMI input where should be connected suitable generator providing following format 1280x720p@60Hz test pattern. A 32 step grey scale is recommended to assess relevant colorimetry tracking and low/high light saturation points.

As some color coordinates discrepancies can be noticed from panel batches to others, it may necessary to perform slight touch-up.

For Color temperature adjustment, switch TV on leading HDMI input where should be connected suitable generator providing following format 1280x720p@60Hz test pattern. A 32 step grey scale is recommended to assess relevant colorimetry tracking and low/high light saturation points.

Make sure Picture Preset is set to “DYNAMIC”

mode, both “Contrast” and “Backlight” bar graph are set to “100”

(maximum), “Gamma” bargraph are set to “0” (2.2 nominal) and that

both “Energy Saving” and “Light Sensor” are set to “Off”

from “ECO Settings” subsection.

Ensure that TV is in Factory mode to access to ”White Balance” adjustment submenu, and then scroll down to toggle off “Pic. Enhance” flag.

PC VGA, CMP YPrPb, SCART RGB, CVBS_PAL/SECAM Gain/Offset matrix offsets locations are relative to HDMI/DTV.

Warm and Cool Tone are relatives to Normal mode. WB adjust need to fix default G Gain .

“Gain” registers set need to be adjusted at 70IRE.

“Offsets” registers set can be adjusted at 30IRE, but it’s not recommended to keep them defaulted.

Note: All matrix offsets locations can be individually fine-tuned.

Ensure that TV is in Factory mode to access to ”White Balance” adjustment submenu, and then scroll down to toggle off “Pic. Enhance” flag.

PC VGA, CMP YPrPb, SCART RGB, CVBS_PAL/SECAM Gain/Offset matrix offsets locations are relative to HDMI/DTV.

Warm and Cool Tone are relatives to Normal mode. WB adjust need to fix default G Gain .

“Gain” registers set need to be adjusted at 70IRE.

“Offsets” registers set can be adjusted at 30IRE, but it’s not recommended to keep them defaulted.

Note: All matrix offsets locations can be individually fine-tuned.

Targets and Tolerances for all inputs

Note: The White balance value is right conformed by PQ Engineer , Except PQ Engineer, anybody cannot change the white balance value and Default value.

The measured and adjustable parameters should be mainly “x”, “y” coordinates (see “TCL EU Picture Quality Requirements for FPDs” for reference).

The signal level check has been down in R&D, Factory should not adjust the scaling Brightness , scaling contrast and scaling saturation.

The White Balance alignment should be performed using a well calibrated and contact less analyzer (ex: CA310).

Note: The White balance value is right conformed by PQ Engineer , Except PQ Engineer, anybody cannot change the white balance value and Default value.

The measured and adjustable parameters should be mainly “x”, “y” coordinates (see “TCL EU Picture Quality Requirements for FPDs” for reference).

The signal level check has been down in R&D, Factory should not adjust the scaling Brightness , scaling contrast and scaling saturation.

The White Balance alignment should be performed using a well calibrated and contact less analyzer (ex: CA310).

The

analyzer may not touch the screen surface, and measurement must be performed in

a dark environment keeping the probe(s) at 90+/-2° from the panel center.

The results should fulfill following TCL matching requirements (Minolta CA210-CH00 based):

The results should fulfill following TCL matching requirements (Minolta CA210-CH00 based):

Cloning

To operate master/golden clone and reuse it further on demand, please to follow below Cloning SOP:

To operate master/golden clone and reuse it further on demand, please to follow below Cloning SOP:

All underused BIN image files need to

be used strictly with MT5531 SoC platform as depending on SW structure.

Other faster access methods via UART/IR commands are available on enclosed SIACP requirements.

Other faster access methods via UART/IR commands are available on enclosed SIACP requirements.

High Pot.

and Insulating Resistance Tests

At the end of the process, a “High

Voltage” and an “Insulating Resistance” tests are required to fulfill Safety Electrical

requirements (CEI 65065)

High Voltage Withstanding requirements > Insulating Resistance requirements

* “Voltage” > 3500 VAC - “Voltage” > 500 VDC

* “Max Leakage Current” > 10 mA - “Threshold Min” > 4M Ω

* “Test Time” > 5 sec - “Test Time” > 3 sec

* “Voltage” > 3500 VAC - “Voltage” > 500 VDC

* “Max Leakage Current” > 10 mA - “Threshold Min” > 4M Ω

* “Test Time” > 5 sec - “Test Time” > 3 sec

SHOP-END

Test

At final process stage, it’s necessary to perform “Reset shop” before any packing to leave Factory mode and restore User default presets.

This function is accessible by selecting “Factory menu àReset Shop”, then pressing RCU “OK/►” key. Other faster methods via UART/IR commands are available on enclosed SIACP requirements.

“Reset Shop” presets should follow “MT5531_EU_OOB_MenuSetting_step1_Base_01.doc” document.

Note: A password might be required in case of Parental Control function is locked, use default “1234” password or “0423” super password to clean-up existing ones if forgotten.

At final process stage, it’s necessary to perform “Reset shop” before any packing to leave Factory mode and restore User default presets.

This function is accessible by selecting “Factory menu àReset Shop”, then pressing RCU “OK/►” key. Other faster methods via UART/IR commands are available on enclosed SIACP requirements.

“Reset Shop” presets should follow “MT5531_EU_OOB_MenuSetting_step1_Base_01.doc” document.

Note: A password might be required in case of Parental Control function is locked, use default “1234” password or “0423” super password to clean-up existing ones if forgotten.

How to upgrade SW FLASH using MTK

tool

Connect UART interface to suitable

manufacturing TV input connector (note that PC connector requires TVs on “Factory mode”)

Launch MTK tool with version above v0.6.7

Set right SoC template (ex: MT53xx)

Launch MTK tool with version above v0.6.7

Set right SoC template (ex: MT53xx)

Select “Tool” button.

Press “Browse” button to select the

corresponding SW bin file to upload (ex: V8-0MT3101-LF1Vxxx.bin)

Supply the SSB to required voltage.

Press “Upgrade” button and appear the below picture.

Supply the SSB to required voltage.

Press “Upgrade” button and appear the below picture.

Select NOR flash type and press “OK”

button to start downloading the SW and wait the gauge displayed “100%” that

means the SW has been successfully downloaded.

In the meanwhile, all operations such erasing flash and so… are parsed into the debug window script.

When upgrade is completed, remove UART

connection.

Restart SSB (chassis) or TV and wait few seconds for EEPROM update.

Remember to perform “Factory menuàReset ALL“ and then press RCU “OK/►” key if there’s not any subsequent cloning operation.

Restart SSB (chassis) or TV and wait few seconds for EEPROM update.

Remember to perform “Factory menuàReset ALL“ and then press RCU “OK/►” key if there’s not any subsequent cloning operation.

How to upgrade FLASH SW using USB: Upgrade

with Loader

Power-off or switch TV to standby (LED should light on)

Copy the corresponding SW PKG image (ex: “V8-0MT310x-LF1Vxxx.pkg”) into USB stick (pen drive) root path and rename it to “upgrade.pkg”

Plug USB stick to the TV.

Power-off or switch TV to standby (LED should light on)

Copy the corresponding SW PKG image (ex: “V8-0MT310x-LF1Vxxx.pkg”) into USB stick (pen drive) root path and rename it to “upgrade.pkg”

Plug USB stick to the TV.

While power-on TV if previously off

(LED status off), press “Power” button from local keyboard during few seconds

to start upgrading process

Release “Power” button once LED is blinking or USB stick starts blinking, TV is uploading SW BIN image

When reflashing is successful, TV should restart automatically after 2min.

Info: If TV doesn’t restart and LED is lightening on, an error may occurred during flashing, check the set, PKG file integrity and try again from 1st step.

Remove USB stick.

Remember to perform “Factory menuàReset ALL“ or “Factory menuàReset Shop“ and then press RCU “OK/►” key if there’s not any subsequent cloning operation.

Switch off TV by removing AC cord.

Reconnect AC cord to restart TV and wait few seconds for EEPROM update.

Note: If “Reset Shop” was performed, a “Welcome Setup” menu should be displayed, otherwise new SW version should be displayed into relevant Factory mode caption info or on bottom of “Factory menu“

Release “Power” button once LED is blinking or USB stick starts blinking, TV is uploading SW BIN image

When reflashing is successful, TV should restart automatically after 2min.

Info: If TV doesn’t restart and LED is lightening on, an error may occurred during flashing, check the set, PKG file integrity and try again from 1st step.

Remove USB stick.

Remember to perform “Factory menuàReset ALL“ or “Factory menuàReset Shop“ and then press RCU “OK/►” key if there’s not any subsequent cloning operation.

Switch off TV by removing AC cord.

Reconnect AC cord to restart TV and wait few seconds for EEPROM update.

Note: If “Reset Shop” was performed, a “Welcome Setup” menu should be displayed, otherwise new SW version should be displayed into relevant Factory mode caption info or on bottom of “Factory menu“

Upgrade without Loader (Customer mode)

Copy the corresponding SW PKG image (ex: “V8-0MT310x-LF1Vxxx.pkg”) into USB stick (pen drive) root path and rename it to “upgrade.pkg”

Plug USB stick to the TV.

TV will automatically detect new SW to upgrade and displays below pop-up message:

Copy the corresponding SW PKG image (ex: “V8-0MT310x-LF1Vxxx.pkg”) into USB stick (pen drive) root path and rename it to “upgrade.pkg”

Plug USB stick to the TV.

TV will automatically detect new SW to upgrade and displays below pop-up message:

Press RCU “OK/►” key to start upgrading process and

follow instructions till reflashing is successful.

Remove USB stick.

Remember to perform “Factory menuàReset ALL“ or “Factory menuàReset Shop“ and then press RCU “OK/►” key if there’s not any subsequent cloning operation.

Switch off TV by removing AC cord.

Reconnect AC cord to restart TV and wait few seconds for EEPROM update.

Note: If “Reset Shop” was performed, a “Welcome Setup” menu should be displayed, otherwise new SW version should be displayed into relevant Factory mode caption info or on bottom of “Factory menu“

Remove USB stick.

Remember to perform “Factory menuàReset ALL“ or “Factory menuàReset Shop“ and then press RCU “OK/►” key if there’s not any subsequent cloning operation.

Switch off TV by removing AC cord.

Reconnect AC cord to restart TV and wait few seconds for EEPROM update.

Note: If “Reset Shop” was performed, a “Welcome Setup” menu should be displayed, otherwise new SW version should be displayed into relevant Factory mode caption info or on bottom of “Factory menu“

How to upgrade FLASH SW using OAD

OAD Re-flashing

Power-on TV

Set TV to Factory mode (enable Factory key) and/or Burn-in mode if necessary.

Connect RF antenna or whatever air antenna with suitable amplifier from any digital broadcasting system (ex: DTA-115 Multi-Standard VHF/UHF Modulator.

Play DVB MPEG SSU TS, that includes suitable PKG SW image, with right presets (850MHz/8MHz/…) detailed on above.

Send OAD manufacturing IR code [08d/60d] (refer to SIACP document rev. v5.9 for further information) or go to “Factory menuàOtheràOAD update“ and then press RCU “OK/►” key.

OAD will start automatically and several pop-up messages such as scanning/searching, downloading and flashing will be skipped (acknowledged by default).

Power-on TV

Set TV to Factory mode (enable Factory key) and/or Burn-in mode if necessary.

Connect RF antenna or whatever air antenna with suitable amplifier from any digital broadcasting system (ex: DTA-115 Multi-Standard VHF/UHF Modulator.

Play DVB MPEG SSU TS, that includes suitable PKG SW image, with right presets (850MHz/8MHz/…) detailed on above.

Send OAD manufacturing IR code [08d/60d] (refer to SIACP document rev. v5.9 for further information) or go to “Factory menuàOtheràOAD update“ and then press RCU “OK/►” key.

OAD will start automatically and several pop-up messages such as scanning/searching, downloading and flashing will be skipped (acknowledged by default).

Once upgrading completed, TV may

restart automatically after warm start and implicit Reset All (in case of NVM

mapping/signature change) in previous Factory and/or Burn-in mode.

How to change ProjectID with RCU

Process following subsequence IR codes

to change projectID: 062598+MENU+xxx (xxx:ProjectID, ex: 003)

Restart TV

Restart TV

How to Upgrade HDCP KEY by UART

Connect UART interface to suitable

manufacturing TV input connector.

Launch MTK tool with version above User Tool: FlashTo0l.exe

Open Flash Tool, Select menu bar Confing Item. Select Flash Download option.

Launch MTK tool with version above User Tool: FlashTo0l.exe

Open Flash Tool, Select menu bar Confing Item. Select Flash Download option.

Click on “Flash Download option” button and Into option menu.

Setting Start Address:0x007b0000, Area Length:0x00010000. Select OK.

Setting Start Address:0x007b0000, Area Length:0x00010000. Select OK.

Select menu upgrade icon

.and Load bin File need Hdcp key.

Select Upgrade Icon.

Select Upgrade Icon.

Attention: If the upgrade is not

successful, Press the computer ESC key when hold on TV, waiting for TV finish

up after the upgrade.

How to upgrade CI Key using USB

Copy corresponding “*.key” files

into USB stick (pen drive) root path, and renamed them as following “TCL_*.key”

if necessary.

Under USB root path, create a new folder named as “XX_” (once the CI key is overwritten, the matching key file will be moved to this folder)

Plug USB stick to the TV

Under USB root path, create a new folder named as “XX_” (once the CI key is overwritten, the matching key file will be moved to this folder)

Plug USB stick to the TV

Go to “Factory menu à Other à Update CI+ Credential à Update From USB“ and then press RCU “OK/►” key.

The “Valid” flag should now be enabled

(turns to “Yes”), “Custom Code” should displayed “TCL” and “Serial Num.” field

should updated with Key number.

Remove USB stick.

Note: If unfortunately the process failed, you may need to download new CI key and repeat operation again.

Remove USB stick.

Note: If unfortunately the process failed, you may need to download new CI key and repeat operation again.

How to upgrade CI Key using MTK tool

Connect UART interface to suitable

manufacturing TV input connector.

Launch MTK tool with version above v2.48-05

Click on “Browse” button and select "All files(*.*)" filter, then browse any “*.key” file.

Modify "Custom Burning Address:" to "790000", then start to upgrade.

Restart TV.

Launch MTK tool with version above v2.48-05

Click on “Browse” button and select "All files(*.*)" filter, then browse any “*.key” file.

Modify "Custom Burning Address:" to "790000", then start to upgrade.

Restart TV.

Go to “Factory menu à Other à Update CI+ Credential à Update CI+ Credential”, and then press RCU ”OK/►” key. The “Valid” flag should now be

enabled (turns to “Yes”), “Custom Code” should display “TCL” and corresponding

“Serial Number” should be updated as well like onto below snapshot:

Remove UART connection.

Note: If unfortunately the process failed, you may need to download new CI key and repeat operation again.

Remove UART connection.

Note: If unfortunately the process failed, you may need to download new CI key and repeat operation again.

How to upgrade MAC address using USB

MAC for USB upgrade method as

following:

Create a new folder (name: _MAC) in the USB disk root directory.

Put the MAC file into the root directory of the USB disk.

Insert the USB disk into TV, in the factory menu, selected other > Update MAC address > Update From USB.

Create a new folder (name: _MAC) in the USB disk root directory.

Put the MAC file into the root directory of the USB disk.

Insert the USB disk into TV, in the factory menu, selected other > Update MAC address > Update From USB.

Note: A quick access to suitable

submenu item can be achieved by pressing it prefixed RCU key number (ex: pressing

“9” to directly highlight “USB Clone” item).

Troubleshooting