The TX-1000 sold in the USA for approximately $8,000 and the Dragon CT

for approximately $2,000 (including a good tone arm). Estimates of the total

number of these turntables sold worldwide range from 200 to 500 for the TX-1000

and 2,000 to 5,000 for the Dragon CT. These numbers are guesstimates as no one

really knows for sure. While the TX-1000 and the Dragon CT are both Nakamichi

turntables, they actually are quite different from one another in both design,

appearance, and materials (cast metal versus wood.)

Despite being so different from each other

the TX-1000 and the Dragon CT share one incredible feature. Both turntables

have a self-centering mechanism that eliminates the wow caused by the spindle

hole being punched off center. All of us who play vinyl

records have seen the effect of an LP with an off-center spindle hole—the

cartridge and arm swings horizontally from side to side with each revolution of

the platter. Likewise, we have heard the pitch of a sustained note rise and

fall with each revolution of the turntable. This is particularly noticeable on

sustained piano notes contained in the last grooves of a side.

Among turntable aficionados the Nakamichi TX-1000 turntable and its smaller brother,

the Dragon Computing Turntable (CT), are legendary. These turntables, like most

classics, are rare. Both turntables were sold from roughly 1983 to 1987 before

being killed off by the ascendancy of the CD. These differences are

understandable when you realize that the TX-1000 was designed by Etsuro

Nakamichi and built by Micro-Seiki, while the Dragon CT was designed by Junichi

Okumura and built by Fujiya Audio Ltd.

"Suppose

we are listening to a groove that is, say, 75 mm from the center of the record;

typically, this is still in the music groove region, but near the end of it.

(Seventy-five millimeters is about three inches.) Since the record goes around

once in 1/(33 1/3) minutes = 1.8 seconds, the velocity of this groove past the

stylus is 2 pi (75mm)/1.8 sec. which equals 261.8 mm/sec. Now suppose the

record is 0.5 mm off center. (This is the limit of the correcting motion of the

Nakamichi TX1000. Records further off-center than that have to be roughly hand

centered before the TX1000 is applied. Most records that do not have badly worn

spindle holes meet this standard of 0.5 mm.) Then when we are hearing the part

of the 75 mm groove that is furthest from the platter center, the effective

radius of the groove is 75.5 mm and the velocity goes up to 263.5 mm/sec. At the

closest part of the groove, the radius is effectively 74.5 mm and the velocity

goes down to 260.1. The ratio between the maximum and minimum velocities is

75.5/74.5 = 1.0134. Thus the pitch of a note recorded in this groove is a

little more than 1.3 percent higher at the part farthest from the platter

center than it is at the part closest. In another viewpoint, the wow is ±0.66

percent. Proportionately, smaller center errors give smaller pitch wow, with

.25 mm giving about 0.33 percent, 0.1 mm giving .13 percent, etc. Smaller

groove radii would give larger wow percentage (inverse proportion) for a given

off-centeredness. Off-center wow is worst at the end of the side. A usually

accepted standard for audibility of wow is 0.1 percent.

This of course varies from

person to person. The pitch discrimination level for A/B matching can be as low

as 0.01 percent in people highly sensitive to pitch. This is of course a

different, probably more sensitive kind of pitch audibility than wow, but in

fact the repeated periodic pitch variations of off-center wow are seemingly

quite close in nature to the A/B test. The TX-1000, in the process of centering

the records, gives read-outs of how far the records are off-center before the

correction. While most meet the 0.5 mm standard, few are centered within 0.1 mm

and almost none at the level of, say, 0.03 mm or less. Moreover, spindle-hole

looseness generates ambiguities that are often on the order of a tenth of a

millimeter, varying with how you put the record on. And, as noted, better than

0.1 mm centering is needed to meet the nominal ± 0.1 percent wow threshold.

(Precisely, at 75 mm groove radius, ±0.1 percent wow corresponds to .075 mm

centering.) In short, it is numerically clear that some correction process is

needed for the vast majority of records, if they are to be audibly pitch

stable."

To summarize, even if your LP is

made with the spindle hole dead-centered, if your spindle hole is .1 mm larger

in diameter than your spindle you will most likely have audible wow. Wow at

this level will probably not be audible as a rising and falling pitch unless

you are very sensitive to pitch instability. However, most people will notice

that the inner details of the music will be blurred or indistinct. Also

consider what is happening to your stereo image as the stylus is forced against

first one side of the groove and then against the other side of the groove with

each rotation of the LP—essentially anti-skating gone crazy.

For those of us

that listen to vinyl on a regular basis we are accustomed to hearing the

consequences of pitch instability caused by off-centeredness. We just chalk

these detriments up as just some of the inherent differences between digital

and vinyl playback.

With

the TX-1000 you can play an LP without using the self-centering feature—this is

called nominal centering. And you can switch back and forth between nominal and

self-centered. Thus, it is easy to hear the difference self-centering makes.

With an LP that is .5 mm off-center, the improvement in sound is very

noticeable—more detail, a more natural, relaxed sound, and none of that

annoying undulating wow on sustained notes.

With LPs that are less than .1

mm off-centered, the sonic difference between nominal and self-centered is not

very audible. However, the TX-1000 gives a digital readout of the off-centeredness of each LP

that it centers. Very few of the hundreds of LPs that I have centered on TX-1000 are off-center by less than .1 mm. Thus, almost all LPs that I play on

my TX-1000 sound better for having been self-centered. There is no doubt that self-centering an LP can significantly improve the quality of the

sound during playback. However, self-centering is meaningless if the turntable

itself is not a good sounding turntable. After all, putting delicious frosting

on a mediocre tasting cake is waste of good frosting.

The

specifications of the TX-1000 as published by Nakamichi in early 1984 (via a

Google translated Japanese sales brochure) stated the signal to noise ratio as

"above 78dB DIN-B". Wow and flutter were stated at "0.003%

(WRMS/FG direct reading method) 0.02% (after WRMS and the center search)".

I am not an engineer and I don't know what these numbers really mean. TX-1000 is currently set up, with a Van den Hul Colibri XPW

mkIII mounted on a Schroeder Reference 9" jacoba tonearm and with the

turntable supported on Stillpoints rather than on its original air bladders,

the sound with nominal centering is wonderful. The sound is detailed, smooth,

musical, has rhythmic drive and arises from a black, black background. With

self-centering, things get even better. I have heard both the

Certus and the Proscenium turntables at audio shows. I suspect that both

turntables sound better than the TX-1000 with nominal centering.

For rock, heavy metal and certain percussive soundtracks pitch stability

or instability is not really that noticeable. For this type of music I use my

Garrard 401turntable with Moerch DP-6 12" arm and Empire 750LTD (moving

magnet) cartridge. I find that this combination of table, arm and cartridge to

be highly synergistic and produces music that has more pace and rhythmic drive

than the TX-1000, Schroeder, Colibri combination. On the other hand, for

classical music, small ensembles, and vocals the TX-1000 combination is, the only way to go.

Besides

how many of you readers ever see a TX-1000 in the flesh let alone

be able to purchase one? The answer is - not many. Vinyl is making a resurgence. New

turntables are coming to market and many of them are quite expensive—much more

expensive than either the TX-1000 or the Dragon CT, which would have cost

roughly $16,000 and $4000, respectively, when their original purchase price is

adjusted for twenty years of inflation. Modern day turntable manufacturers are

reluctant to publish the flutter and wow specifications for their turntables.

However, the rule of thumb is that current belt drive turntables have flutter

and wow of less than .1% and current direct drive turntables have flutter and

wow of less than .05%. The inexpensive ($399 street) Technics SL1200 has

published flutter and wow of .035%. Let us say that your

new $30,000 turntable has flutter and wow of only .015%—an incredibly low

number. Now you put your audiophile approved $40 LP (with the spindle hole

being .25mm off center) on your new turntable. Per figures above,

your flutter and wow just went up to .345% (.015% from the turntable and .33%

from the off centered spindle hole).

The manufacturer of your turntable just

spent $1 million in research and development to bring the flutter and wow down

to an incredibly low .015% and you just paid a portion of that R & D with

your purchase.

A question to you and the manufacturer is: Who cares if flutter

and wow of the turntable is .015%?

What is important is not the flutter and wow

of the turntable by itself, but the flutter and wow of the turntable and LP

combined.

If the flutter and wow of the turntable was .05% that would mean the

flutter and wow of the turntable with the LP would be .380% (.05% + .33%).

Audibly, .380% is not much different from .345%. The difference between .380%

and .345% may not even be audible because the .035% difference is being swamped

by the .33% LP wow.

To my way of thinking, the purchaser of a turntable would

be far better off if the turntable manufacturer spent his R & D money on

developing a self-centering mechanism for his turntable. That would

dramatically lower flutter and wow on playback for the purchaser of the

turntable. Who listens to a turntable spin with no record on it?

What is

important is the flutter and wow with the LP spinning and the stylus in the

groove. Even if all of our LPs were off

center by only .1 mm and all spindle holes were the exact diameter of the

spindle, neither of which is the case, the .380% versus .345% flutter and wow

would only drop to .180% versus .145%. This is still audible and the LP flutter

and wow is still dominating the turntable flutter and wow.

So what

does all this mean for the average vinyl lover. It means nothing if you are not

going to buy a new turntable at some time in the future. However, if you might

be buying that one last turntable some time in the future you might want to

have a little chat on the phone or at the next audio show with your favorite

turntable manufacturer. You might want to give him copy of this article and point out to him that while Manufacturer is spending all his time

trying to drop his flutter and wow from .05% to .04%, there is a 400 kg gorilla

rampaging though the listening room that is making so much noise that all of Manufacturer's time and money spent on achieving a .04% flutter and wow is

meaningless and wasted. If enough of us talk about self-centering, maybe one

manufacturer will actually do it. And if one manufacturer does it, many more

will follow due to competitive pressure. If a dealer is demoing a

self-centering turntable and a non-self-centering table and the tables are

anywhere close in price, the customer will choose the self-centering

turntable the majority of the time. Building a self-centering mechanism is not

as difficult or as expensive as it was in the 1980s. With current micro

processors and servo motors the design and manufacturing of a self-centering

turntable is easier and cheaper (in inflation adjusted dollars) than ever

before.

Both the TX-1000 and the Dragon CT have a

glass top platter on top of a metal sub-platter. A sensor arm is used by both

turntables to measure the off-centeredness of the LP. The top platter is then

automatically moved relative to the sub-platter to correct for the off-centeredness

of the LP. The two turntables make the correction in different ways.

I have never seen a Dragon CT perform its self centering feature.

However, from descriptions of it that I have read on the Web it seems you push

down on the spindle which manually brings the glass top platter into alignment

with the sub-platter and starts the self-centering process. In the picture of the Dragon CT the arm at the back of it is not a tone arm. It is

the sensor arm. Once the self-centering process has been initiated, the sensor

arm moves over to the lead-out groove area of the LP and slowly drops down. The

sensor arm has a stylus at the end of the arm. Once the stylus is caught in the

lead out groove, the sensor arm moves to the lead out lockout groove.

The lead

out lockout groove is in almost all cases, particularly for modern LPs, a

perfect circle. As the LP spins, the sensor arm measures the horizontal

movement of the stylus caused by the off-centeredness of the spindle hole. A

small plunger then comes out of housing next to the platter. The plunger gently

nudges the glass top platter. You may have done something similar to this when

you tried to center an LP with an oversize spindle hole by gently nudging on

the rim of the LP as it spun on the plate. The Dragon CT, however, is very precise

and accurate. After nudging the top platter the Dragon CT measures again,

applies another nudge and continues to measure and nudge until the LP is centered.

Once centering is complete the sensor arm lifts up and retracts to its rest

position.

For the TX-1000 the process is essentially the same.

An LP is

placed on the glass top platter and the 'center search' button is pressed. A

2" x 9" housing to the left of the platter rises up about 2.5",

a brass rod (the sensor arm) rotates out, moves over to the lead out groove

area and drops down. The stylus at the end of the brass rod drops into the lead

out groove and moves the rod to the lead out lockout groove. The turntable

measures the horizontal movement of the stylus and by means of two servo motors

in the sub-platter adjusts the position of the top platter relative to the

bottom platter. After moving the top platter the off-centeredness is again

measured and additional correction applied. For most LPs, the self-centering

measuring and adjusting process takes about ten seconds. On a few LPs, which

are very off-centered, it can take up to thirty seconds. Once the LP is

correctly centered the brass sensor arm lifts up, rotates back into its housing

and the housing drops back into the turntable.

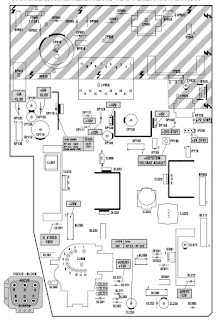

Schematic

Click on the pictures to magnify

Adjustments

Universal Remote Control Codes, Setup procedure, Circuit diagrams and more ....